Back in the Spring I was lucky enough to join Semex and a group of farmers on a trip to Canada and New York state to see how they farm and bring back some ideas.

After a stop off to see Niagara Falls we crossed the border into New York state and got straight onto farm. The first thing we realised was that most of the farms in the area milk for 24 hours a day with a lot of them doing this through one or two side by side herringbone parlours – usually an 80/80 double up. The guys told us this was partly due to making the farm as efficient as possible but also because the banks were reluctant to lend money unless they were milking all day every day!

We visited 10 farms in New York with the smallest being a 3000-cow outfit and the biggest around 7000 cows all on one site. Contrary to what can be a problem in the UK, labour was not hard to source in New York, with a high proportion of Hispanic staff. Many of the staff were highly skilled and could do most things from servicing a tractor to untwisting a uterine torsion! It was great to see such an emphasis on team training and it really showed with how happy the staff were and what a great community they had. It was also law in New York State for the farms to provide accommodation for their staff, if required, and the base pay was equivalent to about £11.50 an hour.

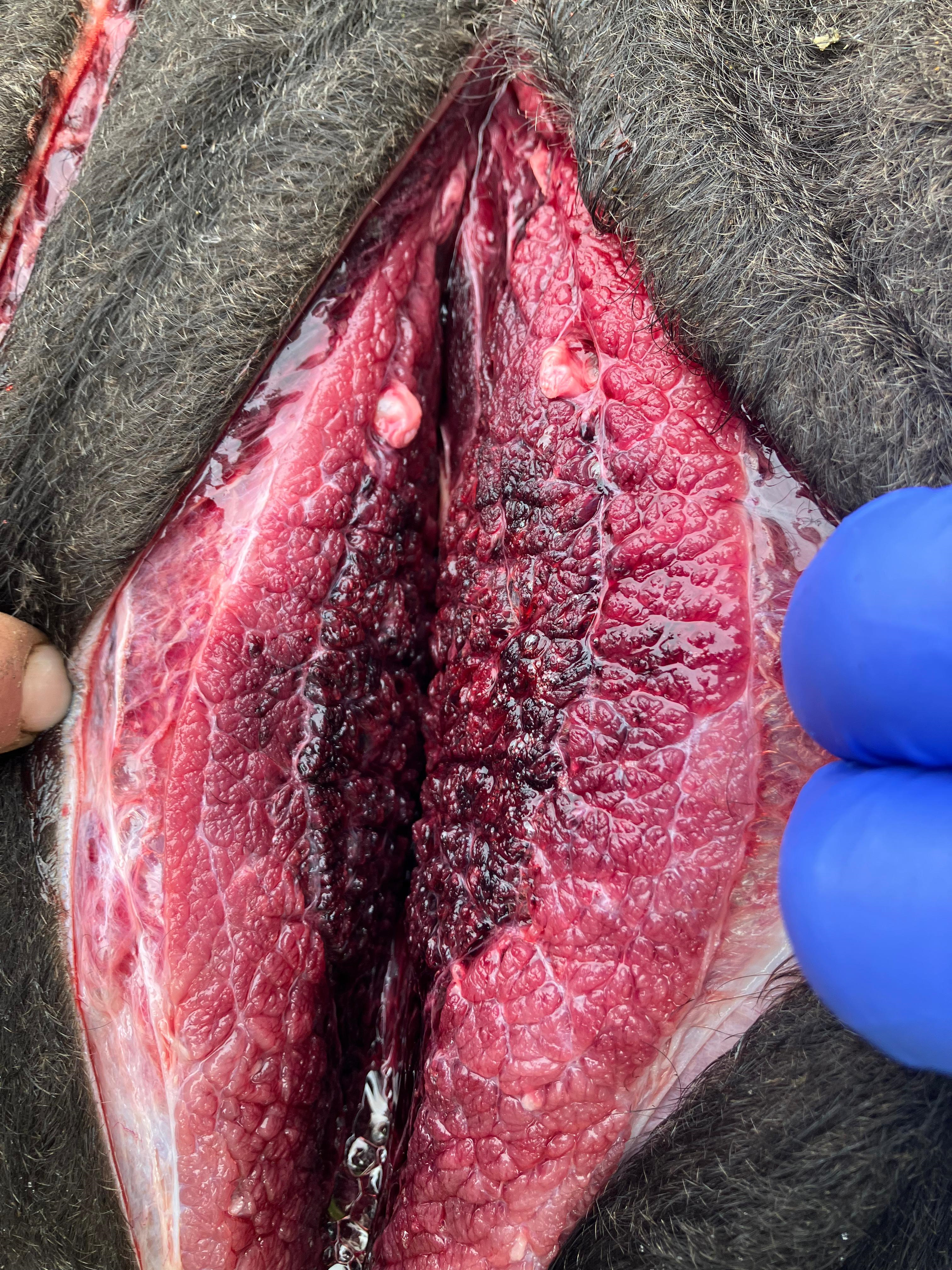

Some farms we visited adopted a “just in time” calving approach and had 1-2 members of staff working on the calving yard 24 hours a day. They moved cows from the cubicles into a straw yard or individual pens at the point where they saw feet showing. There were strict protocols for colostrum management which were monitored with total proteins, like we do here.

In New York, due to the area being so vast, it is difficult to get fallen stock collected promptly so instead some farms have compost piles to put their carcases on. These are incredibly well managed and basically involve a layer of organic matter, like straw, with the animals placed on top along with more straw. The heat of the pile rots the carcase away to just leave bones behind which is then spread on the fields as a fertiliser. It’s worth noting this is not allowed in the UK due to the risk of BSE (mad cow disease) transmission!

After a whistle stop tour of New York, we headed back towards Toronto, Canada and saw a stark contrast to what we’d seen on the other side of the border. The farms here were much smaller, between 100-200 cows and more family-run setups. In Canada they still have “quota” which makes it difficult to expand however, it was seemingly much more profitable. At the time we visited, milk price was around the equivalent of 60ppl.

Both in New York and Canada, I was impressed with how well the cows looked and how they were managed overall. Protocols were set and followed which helped the farms run efficiently and made it easier for new staff to know what was going on.

I am really grateful for the opportunity from Semex to see something different and I would certainly recommend going out there to anybody if the opportunity arises!

Leave A Comment